Why Needle Size for Industrial Overlock Machine Matters: A Comprehensive Guide

Introduction

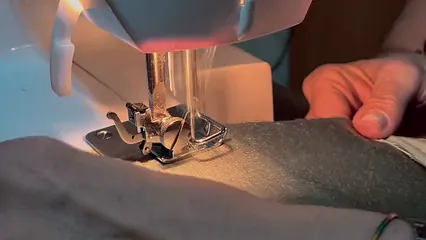

In the bustling realm of industrial sewing, the needle often plays the role of the unsung hero. While we marvel at the intricate fabrics and vibrant threads, the needle works diligently behind the scenes. Just like a superhero needs the right gear, your overlock machine demands the correct needle size to perform at its best. Using the wrong size can lead to a host of headaches, from skipped stitches to unwanted fabric damage.

So, why should you care about needle size? Because the right needle can mean the difference between a flawless seam and a fabric catastrophe. In this guide, we’ll unpack everything there is to know about needle sizes for industrial overlock machines. You’ll learn how to choose wisely, ensuring your sewing projects become masterpieces rather than fumbles.

Get ready to elevate your sewing game and make informed choices that will keep your projects running smoothly. Whether you’re a seasoned pro or just starting, this guide will equip you with the knowledge to select the perfect needle size for your industrial overlock machine.

Summary

Selecting the correct needle size for your industrial overlock machine is paramount. It affects everything from stitch quality to the types of fabrics you can work with effectively. In this article, we’ll dive into how the right needle size impacts your stitching quality, the various fabric types, and specific applications that call for different sizes.

We’ll also shed light on common needle systems, the nuances of needle points, and provide practical tips for choosing the ideal needle size based on your sewing projects. By the end of this article, you’ll grasp the critical role needle size plays in the industrial overlocking world. Armed with this knowledge, you’ll be ready to make choices that enhance your sewing experience and produce beautiful results. With the right needle, every stitch is a step towards sewing success!

How Needle Size Affects Stitch Quality

Choosing the right needle size profoundly impacts stitch quality. It determines how the thread interacts with the fabric, influencing stitch formation and tension. If the needle is too small, the fabric may not feed properly. Conversely, a needle that’s too large can create oversized holes, leading to a messy finish.

Imagine attempting to sew a delicate chiffon with a heavy-duty needle. The result? A fabric that looks like it survived a wrestling match! Skipped stitches can also plague your sewing if the needle struggles to penetrate the material. This can be particularly frustrating when working on intricate designs.

Fabric damage often occurs when using an incorrect needle size. For instance, a needle that’s too thick for lightweight fabric can cause snags or tears. This is a sewing nightmare, especially for those working on high-quality garments.

Choosing the right needle size ensures smooth stitching, preventing these common issues. It’s all about harmony between fabric, thread, and needle.

Understanding the importance of needle size can significantly improve your sewing experience. why needle size for industrial overlock machine

Different Needle Systems for Overlock Machines

Overview of Common Needle Systems

Industrial overlock machines utilize various needle systems, each crafted for specific functions. The most common systems include B27, DBx1, and 135×17. Understanding these systems is crucial for optimal machine performance.

The B27 system is popular for overlock machines, compatible with a range of fabrics. This needle type is available in sizes from 70/10 to 140/22, making it versatile for many applications. For example, if you’re working with lightweight materials like chiffon, a size 70 needle would be ideal. Consider adding a Overlock Machine Needles Set to ensure you have the right sizes on hand!

The DBx1 system is often used in high-speed sewing. It features a rounded shank, which helps reduce needle breakage during operation. Sizes for this system range from 60/8 to 120/19, catering to everything from delicate garments to heavy fabrics.

Finally, the 135×17 system is a favorite among industrial sewing enthusiasts. It accommodates various materials and is compatible with several machine models. Knowing your machine’s requirements is essential when selecting the right needle system.

Choosing the Right Needle System

Selecting the correct needle system goes beyond just compatibility; it involves considering factors like fabric type and machine specifications. Each machine may have unique requirements, so consulting the user manual is vital.

First, check your machine’s compatibility with needle systems. A misfit can lead to poor stitching or even damage. For instance, using a DBx1 needle in a B27 machine could end in disaster.

Next, consider the fabric you plan to work with. Lightweight fabrics need smaller needles, while thicker materials require larger ones. If you’re sewing denim, opt for a bigger needle to handle the thickness.

To identify the correct needle system, start by checking your machine manual. It provides necessary specifications. If you’re unsure, consult with fellow sewing enthusiasts or reach out to the manufacturer for clarity.

Choosing the right needle system is an investment in your sewing journey. With the correct needle, you’ll create beautiful stitches, enhancing the overall quality of your projects. Don’t forget to keep some Sewing Machine Oil handy to keep your machine running smoothly!

Fabric Types and Corresponding Needle Sizes

Choosing the right needle size for different fabrics is crucial. Each fabric type has its own requirements. Using the right needle ensures smooth operation and beautiful results. Let’s break it down by fabric weight.

Lightweight Fabrics

When working with lightweight fabrics like chiffon and silk, needle choice is critical. For these delicate materials, you’ll want to use a smaller needle size. A size 70/10 or 80/12 needle is perfect for chiffon. These sizes minimize the risk of snags and damage.

For silk, a needle with a sharp point is ideal. Consider using a microtex needle, specifically designed for thin, tightly woven fabrics. This needle type glides through silk without causing harm. You can find a great Microtex Needles for Fine Fabrics to make your sewing experience even smoother. Always test on a scrap piece before committing to your project!

Medium Weight Fabrics

Medium weight fabrics, such as cotton and taffeta, require a different approach. A size 80/12 to 90/14 needle works wonders here. Cotton, being a popular choice, benefits from a regular point needle which creates clean seams.

Taffeta, often used in formal wear, can also utilize these sizes. A slightly larger needle, like a 90/14, can help with thicker taffeta layers. The goal is to ensure the needle can penetrate without leaving large holes or damaging the fabric.

Heavyweight Fabrics

Heavyweight fabrics like denim, leather, and upholstery materials demand a sturdy needle. For denim, a size 90/14 or 100/16 needle is recommended. These sizes can handle the thickness and density of the fabric, preventing skipped stitches.

When sewing leather, opt for a leather point needle in size 100/16 or larger. The wedge shape of this needle allows it to pierce leather without tearing. It’s essential for achieving professional-looking seams. Don’t forget to have some Leather Needles for Heavy Fabrics to make your projects easier!

For upholstery materials, a size 110/18 or even 120/19 needle is ideal. These larger needles accommodate the bulk and multiple layers often found in upholstery projects. Your sewing machine will thank you for making the right choice!

The Role of Needle Point and Shape

The needle point and shape are as important as the size. Different fabrics require different needle points to achieve the best results.

Types of Needle Points

There are three primary needle points to consider: regular point, ballpoint, and leather point. Each has unique characteristics suited for specific materials.

Regular point needles are versatile, ideal for woven fabrics. They create sharp stitches and are perfect for general sewing tasks. If you’re working with cotton or taffeta, this is your go-to.

Ballpoint needles feature a rounded tip, which allows them to glide between fabric threads. They are designed for knitted or stretchy fabrics, making them perfect for jerseys and spandex. This prevents snagging and helps maintain the fabric’s integrity. Don’t forget to grab a Ballpoint Needles for Knits to keep your projects on track!

Leather point needles, on the other hand, have a wedge-shaped tip. They are specifically designed for sewing leather, vinyl, and similar materials. This shape prevents tearing and ensures a clean stitch. Choosing the right point can make or break your project!

Choosing the Right Point for Your Fabric

The needle point impacts the stitching quality. Using a regular point on knit fabric can lead to skipped stitches. Conversely, using a ballpoint on woven fabric may create holes. Always match the needle point to your fabric type.

For delicate fabrics, a microtex needle offers precision. For sturdy fabrics, ensure you use a needle that can handle the material’s weight. By choosing wisely, you’ll achieve beautiful, professional results in your sewing projects. And while you’re at it, consider using Fabric Scissors for those clean cuts!

Maintenance and Care for Overlock Machine Needles

Importance of Regular Needle Changes

Needles are the unsung champions of your overlock machine. But even champions must retire! Regular needle changes are vital for maintaining optimal performance. So, how do you know when it’s time to change your needle?

Look for these signs:

- Skipped Stitches: If your machine suddenly resembles a polka dot pattern, it’s time for a new needle.

- Fabric Snags: If your fabric starts to look like it survived a cat fight, the needle is likely dull or damaged.

- Unusual Noises: If your machine sounds like a jazz band gone rogue, that needle might be in trouble.

- Thread Breakage: Frequent thread breakage often indicates a worn-out needle. Your thread shouldn’t play a game of tug-o-war!

Replacing the needle regularly helps prevent these issues. Keeping a fresh needle in your machine means fewer headaches and more smooth sailing through your projects. And while you’re at it, consider investing in a Needle Threader Tool to make threading a breeze!

Tips for Needle Maintenance

Taking care of your needles is just as important as knowing when to change them. Here are some best practices for storage and handling:

- Store Wisely: Keep needles in their original packaging to avoid bending or dulling. A needle case can also do wonders for organization.

- Avoid Moisture: Humidity can lead to rusting. Store in a dry place, preferably in a climate-controlled environment.

- Use the Right Tool: When inserting or removing needles, use the appropriate tools. This avoids unnecessary wear and tear on both the needle and your machine.

- Inspect Regularly: Before starting a project, check your needles for any signs of damage, such as bends or chips. A quick visual inspection can save you from future headaches!

By following these simple tips, you’ll prolong the life of your needles. In turn, that means more successful sewing adventures! And while you’re organizing, consider investing in a Craft Storage Box to keep everything tidy!

Conclusion

Choosing the right needle size for your industrial overlock machine is not just a technicality; it’s essential for achieving high-quality results in your sewing projects. With the right knowledge and resources, you can ensure that your machine operates at its best, producing beautifully finished seams on a variety of fabrics. So, the next time you’re gearing up for a sewing project, remember that the needle you choose can make all the difference! And don’t forget to equip yourself with a Sewing Machine Cover to protect your investment!

FAQs

What size needle should I use for stretchy fabrics?

When working with stretchy fabrics like knits and jerseys, the best choice is a ballpoint needle. Sizes 75/11 or 90/14 are usually ideal. The rounded tip of the ballpoint needle slides between the fabric threads, preventing snags. This is key to maintaining the integrity of your fabric. For heavier knits, consider a size 90/14 needle. It provides enough strength to handle the thickness without damaging the material. Brands like Groz Beckert and Schmetz offer excellent options in these sizes. Always remember to test on a scrap piece first!

Can I use domestic sewing machine needles in an industrial overlock machine?

Short answer? No! Domestic sewing machine needles have a flat shank, while industrial needles are fully rounded. This difference affects how the needle fits into the machine. Using domestic needles could lead to poor stitching or even damage your machine. Stick with needles designed for industrial overlock machines, such as the B27 or DBx1 systems. They’re specifically engineered to handle the demands of high-speed sewing, ensuring a smooth operation.

How often should I change my industrial overlock machine needle?

The frequency of needle changes depends on your sewing habits and fabric types. If you sew daily or work with heavy fabrics, change the needle every 8-10 hours of sewing. For lighter fabrics, you might stretch it to every 10-12 hours. However, if you notice skipped stitches or fabric damage, it’s time for a change. Regularly replacing your needle not only improves stitch quality but also prolongs the life of your machine. After all, a happy needle means a happy sewing machine!

What happens if I use the wrong needle size?

Using the wrong needle size can lead to a series of unfortunate events. Expect skipped stitches, fabric damage, or even thread breakage. A needle that’s too small may struggle to penetrate the fabric, while one that’s too large can create unsightly holes. If you find yourself in this predicament, troubleshoot by switching to the correct needle size. Testing on a scrap fabric can also help you gauge if the new needle resolves any issues. Remember, a little preparation goes a long way in avoiding sewing disasters!

Are there specific brands of needles recommended for industrial overlock machines?

Absolutely! Some popular brands include Groz Beckert, Schmetz, and Singer. Groz Beckert’s B27 needles are known for their durability and range in sizes from 70 to 140. Schmetz offers a variety of needle types, including ballpoint and leather point, suitable for different fabrics. Singer also provides reliable options for overlock machines. Choosing a reputable brand ensures you get quality needles that enhance your sewing performance. Always check compatibility with your specific machine model before purchasing!

Please let us know what you think about our content by leaving a comment down below!

Thank you for reading till here 🙂

All images from Pexels