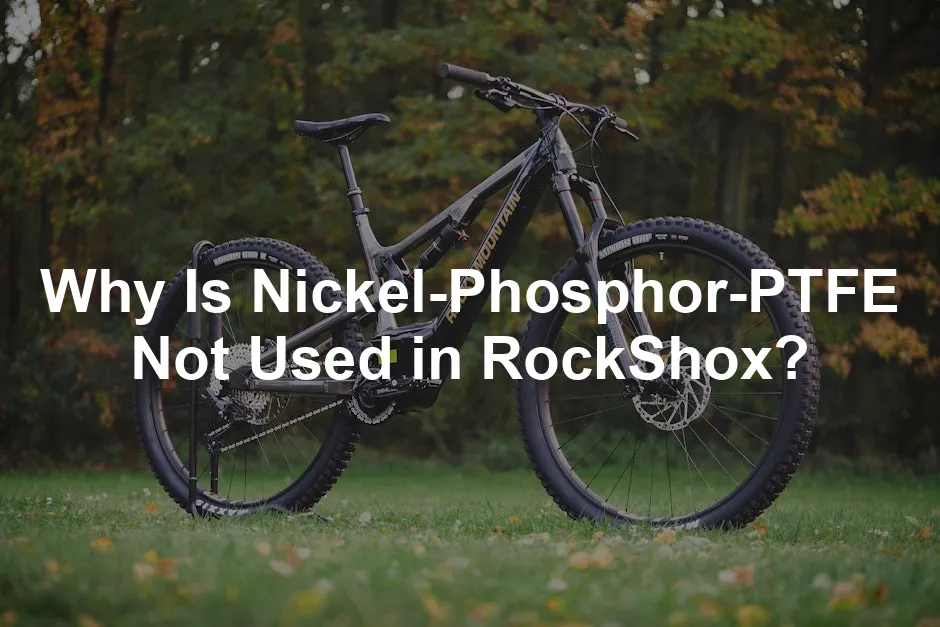

Why Is Nickel-Phosphor-PTFE Not Used in RockShox?

Introduction

In the realm of mountain biking, every detail counts. The choice of materials can significantly impact performance and rider experience. One material that often raises eyebrows is Nickel-Phosphor-PTFE, a composite coating celebrated for its low friction and high wear resistance. With such attractive qualities, it’s puzzling why RockShox, a titan in the mountain bike suspension arena, steers clear of this coating. The truth is, it’s not merely about performance. Factors like compatibility, cost, and the unique demands of mountain biking come into play.

RockShox’s suspension systems are engineered for extreme conditions. They need to absorb shocks and provide a smooth ride over rugged terrain. The materials selected must withstand significant stress while maintaining functionality. Nickel-Phosphor-PTFE may shine in the lab, but the real world demands more.

Consider this: while Nickel-Phosphor-PTFE has impressive properties, it may struggle under the harsh realities of mountain biking. The coating’s performance can diminish over time, especially under repeated impacts. Moreover, the economic aspect cannot be ignored. Higher manufacturing costs can lead to a price tag that doesn’t sit well with budget-conscious bikers.

As we venture deeper into this topic, we’ll uncover the reasons behind RockShox’s material choices. From performance limitations to cost considerations, various elements contribute to the decision to forgo Nickel-Phosphor-PTFE. So, buckle up as we explore why this seemingly perfect coating is left on the shelf when it comes to RockShox suspension systems. Get ready for an insightful ride!

Understanding Nickel-Phosphor-PTFE Coatings

What Is Nickel-Phosphor-PTFE?

Nickel-Phosphor-PTFE is a composite coating made by combining nickel, phosphorus, and polytetrafluoroethylene (PTFE), commonly known as Teflon. This unique blend offers a range of benefits, making it sought after in various industries. Nickel provides strength and corrosion resistance, while phosphorus enhances wear resistance. PTFE contributes the famous non-stick, low-friction properties, allowing components to glide effortlessly.

The history of this coating traces back to industries that demanded durability and efficiency. Automotive and aerospace sectors frequently use it, where components are subjected to extreme conditions. This coating excels in applications requiring low friction, such as gears, valves, and hydraulic systems. Its versatility makes it appealing, but does it fit in the mountain biking world?

Speaking of versatility, if you’re looking to keep your bike in tip-top shape, consider the Mountain Bike Repair Tool Kit. This handy kit ensures that you can tackle any trail mishap without breaking a sweat. Say goodbye to those “uh-oh” moments when you’re miles away from home!

Properties of Nickel-Phosphor-PTFE

- Low Friction: PTFE is the superstar here. It boasts incredible non-stick qualities, significantly reducing friction between moving parts. This means less wear and tear, and a smoother ride. Imagine pedaling uphill without the annoying drag!

- Wear Resistance: The nickel-phosphorus alloy gives this coating impressive durability. It stands tall against scratches and abrasions, essential for components facing constant movement and stress. In the world of mountain biking, where bumps and jolts are part of the ride, durability is a must.

- Corrosion Protection: Nickel-phosphor-PTFE shines under harsh conditions. It can withstand moisture, salt, and other corrosive elements without breaking a sweat. This corrosion resistance is vital for components exposed to the elements, extending their lifespan and performance.

- Chemical Resistance: This coating doesn’t shy away from chemicals either. It resists most substances, making it suitable for environments where exposure to oils, fuels, or other harsh chemicals is common. That’s one less thing to worry about when riding through muddy trails!

While Nickel-Phosphor-PTFE has impressive properties, its application in mountain biking suspension systems, particularly in RockShox products, raises questions. It’s essential to examine the specific demands and challenges faced by suspension components to understand why this coating may not be the go-to choice in high-performance biking.

The Role of Coatings in Mountain Bike Suspension Systems

Importance of Coatings in Suspension Forks

Coatings play a pivotal role in the performance of mountain bike suspension systems. They ensure that suspension forks can absorb shocks effectively while providing a smooth ride over rough terrain. The right coating reduces friction, prevents wear, and protects against environmental challenges like dirt, mud, and moisture.

When you’re flying down a rocky path, your suspension needs to react instantly. High-quality coatings help maintain performance by ensuring that every part works seamlessly together. And speaking of high-quality, if you’re looking to upgrade your ride, check out the RockShox Pike RCT3 Suspension Fork. This fork offers unparalleled performance and responsiveness, making your ride smoother than ever.

Common Coatings Used in RockShox

RockShox employs advanced coatings like Kashima and anodization on its suspension components. Kashima, a proprietary hard anodizing process, provides ultra-low friction and outstanding durability. Anodization enhances wear resistance and corrosion protection, making these coatings perfect for the demanding conditions of mountain biking.

Compared to Nickel-Phosphor-PTFE, these alternatives offer a better balance of performance and durability. They are specifically designed to handle the unique stresses and environmental challenges that RockShox products encounter. And to keep your bike looking sharp, don’t forget to stock up on Bike Cleaning Supplies. A clean bike is a happy bike!

Why Nickel-Phosphor-PTFE Is Not Used in RockShox

Compatibility with Suspension Systems

RockShox products are engineered for peak performance in mountain biking. Suspension systems must endure intense forces and impacts. They require materials that can handle these stresses without compromising performance. Nickel-Phosphor-PTFE, while possessing low friction and wear-resistant properties, may not be the right fit for these specific needs.

One primary concern is the compatibility of Nickel-Phosphor-PTFE with the materials used in RockShox components. Suspension systems are intricate assemblies. The interaction between various materials must be harmonious. Nickel-Phosphor-PTFE could potentially disrupt this balance. For instance, its stiffness might interfere with the precise movement required in suspension forks. RockShox needs materials that provide optimal stability and responsiveness, and Nickel-Phosphor-PTFE may not deliver this.

Moreover, the bonding of Nickel-Phosphor-PTFE with aluminum or other materials used in RockShox components could present additional challenges. Incompatibility may lead to uneven wear or even premature failure of the components. RockShox has a rigorous testing process. They carefully select materials that can withstand the demanding conditions of mountain biking while ensuring they work well with one another.

Performance Under High Stress

Mountain biking is a sport defined by its challenges. Riders experience jumps, drops, and rough terrain. This means that suspension systems must perform reliably under high-stress conditions. Nickel-Phosphor-PTFE, despite its durability, may struggle to maintain its integrity under repetitive impacts and stress cycles.

Case studies show that other materials used in RockShox products, like anodized aluminum and Diamond-Like Carbon (DLC), outperform Nickel-Phosphor-PTFE in high-stress scenarios. For example, during stress tests, Diamond-Like Carbon (DLC) Coating Spray has demonstrated superior resilience against wear and tear. This ensures that the suspension remains responsive over time, crucial for the demanding nature of mountain biking. Riders need components that won’t falter after a few hard rides, and Nickel-Phosphor-PTFE may not guarantee that level of performance.

Moreover, as suspension components endure continuous compression and rebound cycles, any coating must be able to resist degradation. Nickel-Phosphor-PTFE can wear down, leading to increased friction and reduced efficiency. In the world of mountain biking, where performance is everything, even slight degradation can affect the ride quality significantly.

Environmental Factors

Mountain biking takes place in diverse environments. Riders encounter dirt, mud, water, and varying temperatures. These elements can challenge suspension components, making material selection critical. Nickel-Phosphor-PTFE has good chemical resistance, but how does it hold up against the harsh conditions of mountain biking?

RockShox products often face exposure to dirt and moisture, which can lead to corrosion and wear. While Nickel-Phosphor-PTFE offers some level of protection, it might not perform as well as coatings like Kashima, which are specifically designed for these conditions. Kashima coatings are known for their exceptional durability against abrasive materials and environmental elements. In contrast, Nickel-Phosphor-PTFE may not provide the same level of protection over time.

Furthermore, moisture can also affect the performance of Nickel-Phosphor-PTFE coatings. If the coating fails to adhere properly or begins to degrade, it could lead to increased friction and wear. RockShox relies on materials that not only resist corrosion but also maintain their integrity when faced with environmental challenges.

Cost and Manufacturing Considerations

Cost is a significant factor in any manufacturing process, and RockShox is no exception. The application of Nickel-Phosphor-PTFE coatings can be more expensive than traditional methods. This higher cost could lead to increased prices for consumers, which may not be justifiable given the performance benefits.

Manufacturing processes involving Nickel-Phosphor-PTFE may also require specialized equipment. Integrating such processes into existing production lines could disrupt efficiency. RockShox aims for streamlined manufacturing, and adding complexity may slow down production.

In contrast, methods like anodization and DLC coatings are more cost-effective and easier to implement. These alternatives provide similar, if not superior, performance benefits without the added expense and complexity. Cost savings in manufacturing can be passed on to consumers, allowing RockShox to maintain competitive pricing.

In conclusion, while Nickel-Phosphor-PTFE boasts some appealing properties, it simply does not meet the specific demands of RockShox suspension systems. Compatibility issues, performance limitations under stress, environmental factors, and cost considerations all contribute to this decision. RockShox continues to prioritize materials that ensure durability, reliability, and optimal performance, aligning perfectly with the rigorous demands of mountain biking.

Alternative Coatings

Overview of Alternative Solutions

RockShox has made a name for itself in the mountain biking world, and part of that reputation comes from its savvy choice of materials. Instead of Nickel-Phosphor-PTFE, RockShox employs alternative coatings like anodized aluminum and Diamond-Like Carbon (DLC).

Anodized aluminum is lightweight and corrosion-resistant, ensuring that components can endure tough conditions. The anodization process creates a thick oxide layer, which not only enhances durability but also reduces friction. This means smoother rides over rugged trails without compromising on strength. And if you’re looking for some anodized components, check out these Anodized Aluminum Bike Spacers. They add that extra touch of flair while keeping your bike functional!

DLC, on the other hand, is a superhero in the coatings world. It boasts ultra-low friction properties and exceptional wear resistance. This means that components coated with DLC can handle the relentless stress and impacts of mountain biking. Riders can trust that their suspension systems will remain smooth and efficient, even after countless rides through rough terrain.

These alternative coatings provide improved performance and durability, making them ideal for the unique challenges of mountain biking. They ensure that RockShox products maintain their integrity while delivering a fantastic riding experience.

Benefits of RockShox’s Material Choices

The materials chosen by RockShox come with a plethora of advantages. First, the anodized aluminum and DLC coatings significantly enhance the longevity of suspension components. Riders can ride hard, knowing their gear is built to last.

Industry experts rave about these materials. According to a leading bike technician, “The performance and reliability of RockShox suspension systems stem from their innovative material choices.” Furthermore, tests indicate that DLC-coated components experience much less wear and tear compared to those with Nickel-Phosphor-PTFE.

Additionally, RockShox’s coatings are economical. With lower maintenance costs and longer-lasting performance, riders save money in the long run. It’s a win-win! And speaking of savings, if you’re looking to fuel your rides, don’t forget to grab some Energy Gel for Cyclists. Keeping your energy up on the trail is key!

In conclusion, RockShox’s alternative coatings not only elevate the performance of their suspension systems but also ensure that mountain bikers enjoy a reliable, smooth ride for years to come. Riders can embrace the thrill of the trail, confident that their equipment is supported by state-of-the-art materials.

Conclusion

In conclusion, while Nickel-Phosphor-PTFE exhibits desirable properties such as low friction and excellent corrosion resistance, it ultimately falls short in meeting the specific demands of RockShox suspension systems. The rigorous environment of mountain biking necessitates materials that can withstand high stress, environmental challenges, and compatibility with other components. RockShox’s commitment to performance and durability is reflected in their choice of alternative coatings, ensuring that riders enjoy the smoothest and most reliable ride possible. Understanding these material choices not only enhances our appreciation of bicycle technology but also informs future innovations in the industry.

Environmental factors can significantly impact performance in various settings, including mountain biking. Why do environmental factors contribute to glossophobia in the workplace is an interesting exploration of how surroundings affect performance.

Why is Nickel-Phosphor-PTFE not used in RockShox?

Nickel-Phosphor-PTFE is not a preferred choice for RockShox due to several significant reasons. First, this coating can struggle under high-stress conditions typical in mountain biking. It may wear down quickly, leading to increased friction, which is a no-go for performance. Second, compatibility issues arise when Nickel-Phosphor-PTFE interacts with other materials in RockShox products. The unique demands of suspension systems require a harmonious blend of materials that can withstand intense forces without compromising performance. Lastly, cost plays a critical role. The production processes for applying Nickel-Phosphor-PTFE are often more expensive than alternatives, making it an impractical choice for a brand focused on providing high-quality yet affordable products.

What coatings are commonly used in RockShox suspension systems?

RockShox employs a variety of advanced coatings to enhance performance. Commonly used coatings include anodized aluminum and Kashima. Anodized aluminum provides excellent wear resistance and corrosion protection. Meanwhile, Kashima is known for its ultra-low friction properties, allowing for smoother operation. These coatings not only improve performance but also ensure durability in harsh riding conditions, making them ideal for mountain biking.

What are the benefits of Nickel-Phosphor-PTFE coatings?

Nickel-Phosphor-PTFE coatings shine in specific contexts outside of mountain biking. Their low friction properties make them perfect for applications where smooth operation is key. Industries like automotive and aerospace benefit from these coatings due to their high wear resistance and corrosion protection. Additionally, their chemical resistance adds value, allowing them to withstand harsh environments, which is advantageous in many industrial applications.

Is cost a factor in the choice of coatings for RockShox?

Absolutely! Cost is a significant factor influencing the choice of coatings for RockShox products. Nickel-Phosphor-PTFE coatings can be more costly to apply than traditional methods like anodization or DLC coatings. This price difference can affect the overall pricing strategy for RockShox, as they aim to offer competitive pricing without sacrificing quality. By choosing more cost-effective materials, RockShox can maintain affordability while still delivering high-performance products.

Can Nickel-Phosphor-PTFE be used in any biking components?

While Nickel-Phosphor-PTFE isn’t suitable for suspension systems, it could find a place in other biking components where lower stress and friction reduction are priorities. For example, it may be applicable in parts that don’t face the same intense conditions as suspension systems. Components like gears or bearings could potentially benefit from this coating, provided the environmental and performance conditions align better with its properties.

How does RockShox ensure the durability of their suspension systems?

RockShox employs rigorous testing and a careful selection of materials to ensure durability. They utilize advanced coatings like anodized aluminum and DLC, which are specifically designed to endure the stresses of mountain biking. Moreover, RockShox conducts extensive field testing to validate the performance of their components in real-world conditions. This commitment to quality ensures that riders can trust their suspension systems to perform reliably across varied terrains and challenges.

Please let us know what you think about our content by leaving a comment down below!

Thank you for reading till here 🙂

All images from Pexels