Why Is a Mortar Mixer Different from a Cement Mixer?

Introduction

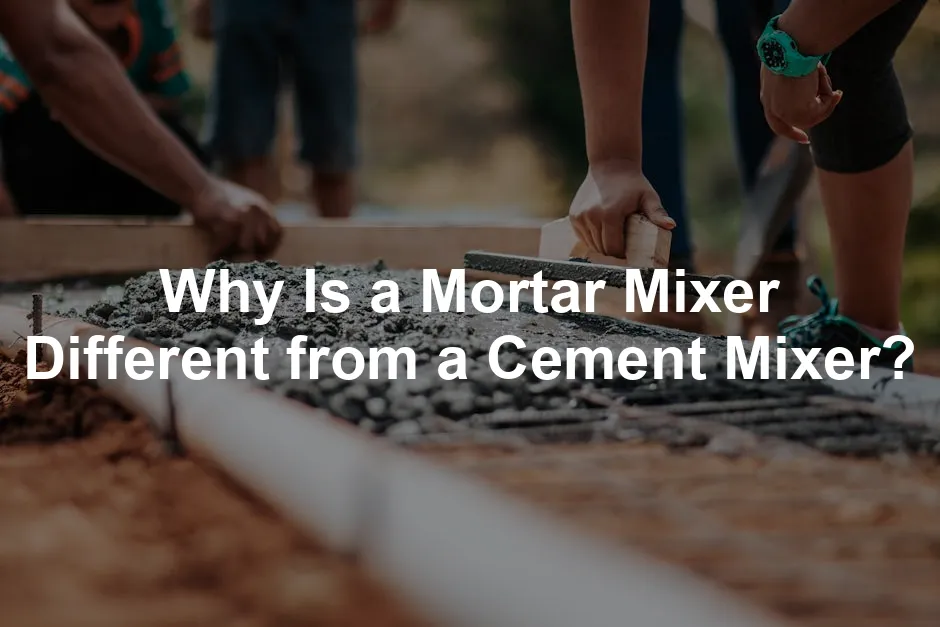

In the bustling world of construction, knowing your tools is half the battle. Among the plethora of equipment, mortar mixers and cement mixers often find themselves at the forefront of confusion. At first glance, they may look like twins separated at birth. However, these mixers have distinct roles that cater to different materials. Using one in place of the other can lead to disastrous results—imagine trying to bake a cake using a lawnmower instead of a mixer!

So, what’s the deal? Mortar mixers are designed specifically for mixing mortar—a blend of cement, sand, and water, perfect for bonding bricks and stones. They focus on achieving a creamy, consistent texture that makes masonry work a breeze. On the flip side, cement mixers are the heavyweights, built to mix concrete, which includes coarser aggregates like gravel and sand. Their design ensures that the mixture can handle hefty structural demands.

If you’re serious about your construction projects, a Mortar Mixer 3 Cubic Feet can be your best friend. It’s compact enough for home use yet powerful enough for larger jobs, ensuring your mortar is mixed to perfection every time.

Summary

Understanding the distinctions between mortar mixers and cement mixers is crucial for any construction project. Mortar mixers are specialized machines designed to mix mortar—a combination of cement, sand, and water—ideal for bonding bricks and stones. They operate with stationary drums and internal paddles that ensure a consistent texture, making them perfect for masonry tasks. On the other hand, cement mixers are robust, designed to handle coarser materials like gravel, and feature rotating drums that facilitate mixing large quantities of concrete for structural applications.

This article will explore the following key points:

- The fundamental differences between mortar and cement, especially in terms of consistency and composition.

- The design and functionality of each type of mixer, including their respective mixing mechanisms.

- The ideal applications for each mixer, highlighting project types that benefit from their specific features.

- Practical considerations when choosing the right mixer for your needs, including capacity, maintenance, and cost.

By the end of this exploration, you’ll be equipped with the knowledge to make informed decisions when tackling your construction projects. And hey, while you’re at it, don’t forget to grab a Cement Mixer Electric 1/2 HP for those big concrete jobs!

Understanding Mortar Mixers

What Is a Mortar Mixer?

A mortar mixer is a specialized machine designed for mixing mortar, a blend of cement, sand, and water. Its primary function is to create a smooth, homogeneous mixture ideal for masonry projects. Unlike cement mixers, mortar mixers feature a stationary drum and internal paddles. These paddles rotate within the drum, effectively mixing the sticky ingredients.

Mortar mixers come in various sizes, typically ranging from 1 to 10 cubic feet. Smaller models are perfect for DIY projects, while larger ones cater to more extensive construction needs. Their design allows for a consistent texture, crucial for applications requiring precision. And don’t forget a sturdy Wheelbarrow Heavy Duty to transport your materials!

Applications of Mortar Mixers

Mortar mixers excel in several specific applications. They are ideal for:

- Bricklaying: The smooth texture of mixed mortar ensures strong bonding between bricks.

- Plastering: A consistent mix allows for an even application on walls.

- Tile Setting: Mortar mixers create the perfect adhesive for tiles, ensuring durability.

The benefits of using a mortar mixer for these tasks are substantial. The design minimizes air pockets, leading to a stronger bond. Moreover, the ability to achieve a uniform consistency reduces the risk of application issues, allowing for better quality control. And let’s not forget about safety—protect your eyes while working with some Safety Goggles for Construction!

Mixing Mechanism and Efficiency

The mixing process in a mortar mixer is simple yet effective. As the internal paddles rotate, they scrape the sides of the stationary drum. This action ensures all components are thoroughly combined, preventing clumps and ensuring a smooth mixture.

Achieving a consistent texture is vital in mortar mixing. A uniform mix results in better adhesion and durability in construction. By using a mortar mixer, contractors can ensure their mortar is well-prepared, leading to higher quality work and fewer issues down the line. Whether you’re a seasoned professional or a DIY enthusiast, understanding the importance of this mixing mechanism can significantly impact your project’s success. And hey, don’t forget some Construction Gloves Heavy Duty to keep your hands safe!

Key Differences Between Mortar Mixers and Cement Mixers

Material Compatibility

Mortar mixers and cement mixers handle different materials. Mortar mixers are designed for mixing mortar, a blend of cement, sand, and water. This mixture is smooth and creamy, perfect for bonding bricks or tiles. Cement mixers, however, are built for concrete, which includes coarser aggregates like gravel and stones.

Using the wrong mixer can lead to issues. For instance, putting cement in a mortar mixer can damage its internal paddles and rubber strips. The thick mixture can cause clogs, making it a costly mistake. Conversely, mixing mortar in a cement mixer may not yield a consistent blend. The coarser texture of concrete doesn’t mix well, resulting in a subpar product. So, using the right mixer is essential for maintaining equipment and achieving quality results. And to keep everything organized, grab a Construction Tape Measure to ensure your measurements are spot on!

Design and Functionality

Let’s take a closer look at how these machines differ in design. Mortar mixers feature a stationary drum with internal paddles. These paddles rotate inside the drum, scraping the sides to ensure everything is thoroughly mixed. This design is perfect for the sticky nature of mortar, allowing for an even and smooth texture.

On the flip side, cement mixers have a rotating drum that tumbles the materials. This design is better suited for mixing coarse aggregates. The rotation keeps the mixture moving and prevents settling, ensuring a homogenous blend. So, while both mixers serve a similar purpose, their designs cater to their specific material requirements. And for those long work hours, consider a Portable Job Site Radio to keep the tunes flowing!

Capacity and Size

When discussing capacity, mortar mixers typically have a smaller volume. They usually range up to 10 cubic feet, making them ideal for small to medium projects. This smaller capacity is perfect for tasks like bricklaying or plastering, where precision is vital.

Cement mixers, however, are built for larger projects. They can handle 12 cubic feet or more, making them suitable for extensive construction needs. This larger capacity is essential for pouring foundations or large slabs, where significant volumes of concrete are required. Choosing the right size ensures efficiency and effectiveness in your projects. And why not make your life easier with a Heavy-Duty Extension Cord for those hard-to-reach outlets!

Mixing Action

The mixing action is another critical difference. Mortar mixers utilize a vertical mixing action, which is perfect for achieving the creamy consistency needed for mortar. The paddles work to fold and mix the ingredients without introducing excess air, resulting in a smooth mixture.

In contrast, cement mixers employ a horizontal mixing action. This design allows for a tumbling effect that effectively incorporates larger aggregates into the mix. The rotation ensures that all materials are evenly distributed, creating a strong and durable concrete. And for the ultimate finish, consider a Concrete Finishing Trowel for that professional touch!

Ideal Applications

Lastly, let’s take a look at the ideal applications for each mixer. Mortar mixers excel in tasks requiring a fine, consistent mixture. They are perfect for projects like bricklaying, tile setting, and stucco application. The smooth finish they provide is essential for these applications, ensuring strong bonds and quality results.

Cement mixers, on the other hand, are indispensable for large-scale construction projects. They’re used for mixing concrete for foundations, driveways, and other heavy-duty applications. Their ability to handle coarse aggregates makes them the go-to choice for any substantial construction job. And don’t forget the importance of a Dust Mask for Construction Work to keep those lungs safe!

In conclusion, understanding these differences is vital for selecting the appropriate mixer for your project. Whether you’re bonding bricks with a mortar mixer or pouring concrete with a cement mixer, using the right equipment ensures quality results and a successful construction endeavor.

FAQs

What happens if I use a cement mixer for mortar?

Using a cement mixer for mortar can lead to a mix that’s too coarse. The paddles aren’t designed for the sticky consistency of mortar. This can also damage the mixer, leading to costly repairs or replacements.

Can a mortar mixer handle concrete?

No, a mortar mixer isn’t made for concrete. Its design focuses on sticky materials, and using it for concrete can cause clogs and wear down the mixer. Stick to mortar for this equipment!

How do I maintain my mixer?

Regular cleaning is key! For mortar mixers, rinse out the drum and paddles with water after each use. For cement mixers, a pressure washer can help clear out any residue. Always check for wear and replace any damaged parts promptly.

What are the costs associated with renting vs. buying a mixer?

Renting a mixer can be cost-effective for short-term projects, usually ranging from $50 to $150 per day. Buying, however, can cost anywhere from $1000 to several thousand dollars, depending on the type and size. Consider your project needs before deciding.

Are there hybrid mixers available that can do both?

Yes! Some hybrid mixers are designed to handle both mortar and concrete. They provide versatility for various projects, but always check the manufacturer’s specifications to ensure compatibility with your materials.

Please let us know what you think about our content by leaving a comment down below!

Thank you for reading till here 🙂 And if you’re looking to enhance your skills, check out Book: “Masonry Skills” by Richard T. Kreh for some expert tips!

All images from Pexels