Why Does CuNi Change Color in Water So Fast?

Introduction

Have you ever noticed how CuNi alloys change color quickly when submerged in water? CuNi, short for copper-nickel alloys, is widely used in marine applications, electrical components, and decorative items. This rapid color change is intriguing and raises questions about the underlying processes. In this article, we’ll uncover why CuNi changes color so fast when exposed to water.

While you’re diving into the fascinating world of CuNi, why not arm yourself with some knowledge? Grab a copy of Copper-Nickel Alloys: Properties and Applications to deepen your understanding!

Summary and Overview

CuNi alloys consist primarily of copper and nickel, often containing varying percentages of other elements like iron and manganese. This unique composition contributes to their desirable properties, such as excellent corrosion resistance. Understanding the color change phenomenon in CuNi is vital for several reasons.

For instance, color changes can affect the durability and aesthetic appeal of marine structures like ship hulls. Additionally, in electrical applications, color alteration might indicate changes in conductivity or integrity. By grasping the chemical processes behind this phenomenon, we can better manage CuNi in various environments and applications.

In the following sections, we’ll explore the chemical reactions involved in this color change, setting the stage for a deeper understanding of the topic. And hey, while you’re at it, make sure you have the right tools! Check out these Heavy Duty Work Gloves to keep your hands safe while working with metals!

Understanding CuNi Alloys

What is CuNi?

CuNi, or copper-nickel, is an alloy made primarily of copper and nickel. The most common grades contain about 70% copper and 30% nickel. This unique combination results in several desirable properties, including excellent corrosion resistance and good thermal conductivity.

CuNi alloys find extensive use across various industries. In marine applications, they are ideal for ship hulls and seawater piping due to their resistance to corrosion. In electrical applications, they serve as components in connectors and circuit boards, thanks to their conductivity and strength.

Understanding the properties and behaviors of CuNi is essential for industries that rely on its performance. One fascinating aspect is how CuNi changes color quickly when submerged in water. This rapid color change is not just a visual alteration; it involves complex chemical reactions that are crucial to grasp for effective use in practical applications.

If you’re intrigued by the applications of CuNi, consider diving deeper with Corrosion Engineering: Principles and Practice, a book that will surely enhance your knowledge!

Physical and Chemical Properties of CuNi

CuNi alloys boast unique properties that make them ideal for various applications. Their corrosion resistance stands out, especially in marine environments. This means they withstand harsh conditions and last longer. Ductility is another essential property, enabling these alloys to be shaped without breaking. This flexibility is crucial in manufacturing processes.

When comparing CuNi to other copper alloys, notable differences emerge. For instance, CuNi offers better resistance to corrosion than standard copper. Its nickel content enhances mechanical strength, making it more suitable for demanding applications, such as shipbuilding and electrical components.

The nickel content in CuNi significantly influences its characteristics. Higher nickel percentages increase corrosion resistance and overall strength. This makes CuNi alloys versatile across industries, ensuring reliability in challenging environments.

The Color Change Phenomenon

What Causes the Color Change in CuNi?

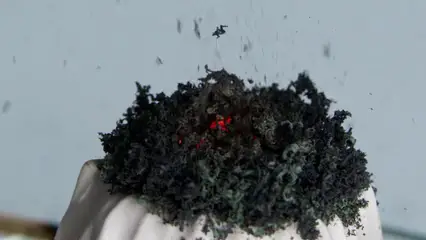

When CuNi alloys are submerged in water, they undergo rapid color changes. This occurs due to specific chemical reactions. Initially, when placed in water, copper begins to react with oxygen and moisture. This interaction leads to the formation of copper oxides.

Oxidation plays a crucial role in this color change. The presence of oxygen accelerates the process, causing the copper to develop a darker hue. Environmental factors, like temperature and pH levels, can further influence the speed of this reaction.

Interestingly, the color change in water differs from that in air. In water, the oxidation occurs more quickly due to the continuous exposure to moisture. This rapid reaction leads to noticeable color changes in a short time, making CuNi alloys visually dynamic in aquatic environments.

The Role of Environmental Factors

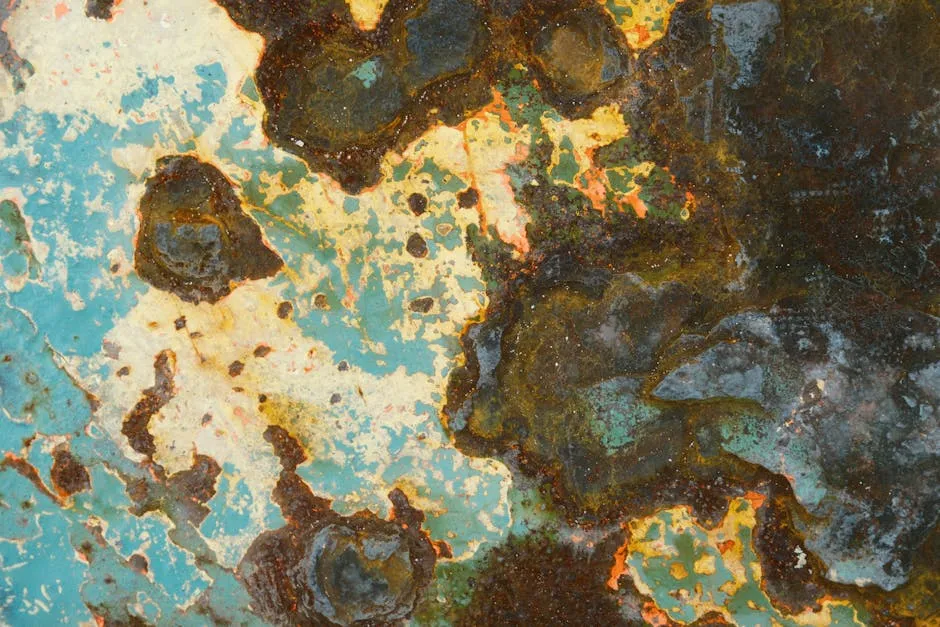

CuNi’s color change in water is influenced by several environmental factors. pH levels play a significant role. When water is more acidic, it can accelerate oxidation, leading to faster color changes. Conversely, alkaline conditions may slow the process down.

Temperature also impacts the speed of the reaction. Warmer water tends to speed up chemical reactions, which means color changes happen more rapidly. Think about how your car engine runs hotter in summer; the same principle applies here! Understanding temperature’s impact is crucial for various applications.

Temperature plays a significant role in chemical reactions, affecting how CuNi changes color in different environments. why does temperature matter mazda mx-5 automatic transmission fill

Impurities in the water, such as salts or other metals, can further alter how CuNi reacts. For example, seawater, rich in salt, can cause more aggressive oxidation compared to fresh water.

Different environments create unique conditions for CuNi. In a marine setting, the constant movement of water and the presence of salt can lead to quicker and more pronounced color changes. In contrast, a still, freshwater lake might not produce the same effect.

Chemical Reactions Behind the Color Change

The primary reason for CuNi’s color change is oxidation. When CuNi is submerged, copper reacts with oxygen in the water. This reaction forms copper oxides, which can change the alloy’s appearance.

Initially, copper reacts with oxygen to create copper(I) oxide (Cu2O), which has a reddish hue. As oxidation continues, it can form copper(II) oxide (CuO), which appears black. In moist environments, additional reactions can lead to the formation of green compounds like copper carbonate or copper sulfate, resulting in various color changes.

These chemical reactions are essential to understand, especially for industries using CuNi in marine or electrical applications. They not only affect aesthetics but also the performance and longevity of the material.

Understanding these reactions helps in predicting how CuNi will behave in different settings, ensuring it meets the requirements of various applications effectively. And for those who love a bit of DIY, don’t forget to check out a Digital Multimeter for Electrical Testing to measure your circuits with confidence!

Practical Implications

Effects on CuNi Applications

The rapid color change in CuNi alloys can significantly impact various applications. In marine settings, such as ship hulls, color alterations may indicate corrosion or material degradation. This can compromise vessel integrity over time. Additionally, color changes can affect the aesthetic appeal of decorative items made from CuNi.

In electrical components, changes in color might signal potential conductivity issues. This is crucial because electrical performance relies heavily on the alloy’s integrity. Any alteration could lead to malfunction or inefficiency.

Understanding these implications helps manufacturers and users make informed decisions about maintenance and application suitability. And for those involved in marine applications, consider upgrading your gear with Marine Grade Stainless Steel Fasteners for maximum durability!

Maintenance and Care of CuNi Products

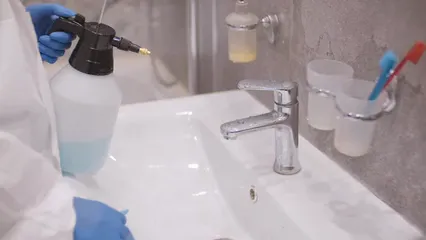

To prevent or manage the color change in CuNi, several maintenance practices are advisable. First, consider applying protective coatings. These coatings act as barriers against moisture and oxidizing agents, minimizing direct contact with harmful elements.

Regular cleaning is essential to remove contaminants that may accelerate oxidation. Simple soap and water can suffice for routine maintenance. Additionally, periodic inspections can help identify early signs of corrosion or color changes, allowing for timely interventions.

Understanding the importance of these practices ensures that CuNi products maintain their appearance and functionality throughout their lifespan. And if you find yourself in need of safety gear, don’t overlook a pair of Chemical Resistant Safety Goggles to protect your eyes during maintenance!

Conclusion

In summary, the color change in CuNi alloys is a fascinating phenomenon driven by chemical reactions, particularly oxidation. This transformation has practical implications for various applications, from marine structures to electrical components. By recognizing the factors influencing color change, users can better manage CuNi in their specific contexts.

Understanding this process not only helps in maintaining the aesthetic appeal but also preserves the functionality and longevity of CuNi products. We encourage readers to consider the environmental factors that may influence this color change in their applications. Understanding these environmental factors can enhance your approach.

Considering environmental factors is essential for understanding how CuNi behaves in various applications. why do environmental factors contribute to glossophobia in the workplace

And before you go, don’t forget to equip yourself for any adventure with a Waterproof Bluetooth Speaker to enjoy your favorite tunes while working or relaxing!

Please let us know what you think about our content by leaving a comment down below!

Thank you for reading till here 🙂

All images from Pexels