Why Is an Annealed Piece Easier to Cut?

Why Is an Annealed Piece Easier to Cut?

Annealing is a crucial heat treatment in metallurgy. It alters a material’s properties to improve its workability. In this section, we’ll uncover why annealed materials are easier to cut than their non-annealed counterparts. Understanding this concept is vital for professionals in manufacturing and metalworking, as it directly influences efficiency and product quality.

If you’re diving deeper into metalworking, consider picking up The Complete Guide to Metalworking. This book offers a wealth of knowledge on techniques and tools that can elevate your skills and efficiency in the workshop.

What Is Annealing?

Definition and Purpose

Annealing is a heat treatment process that modifies the physical and sometimes chemical properties of materials. By heating a material above its recrystallization temperature, then cooling it slowly, we can improve ductility and lower hardness. This transformation makes the material easier to work with, enhancing its machinability.

Historically, annealing dates back to the Middle Ages. Blacksmiths discovered that heating metals and allowing them to cool gradually prevented cracking and brittleness. The process facilitates atomic movement within the metal’s structure, allowing dislocations to be rearranged. As a result, the material becomes softer and more pliable.

Annealing significantly affects metallurgical properties. Increased ductility means that metals can be stretched or shaped without breaking. Conversely, reduced hardness allows for smoother cutting and processing. The balance of these properties is essential for many applications across industries, from automotive to aerospace. Understanding how annealing works is fundamental for anyone dealing with metalworking or manufacturing.

For a comprehensive understanding of metalworking processes, grab a copy of Machining Fundamentals. It provides a solid foundation for anyone wanting to master the art of machining.

Why Are Annealed Pieces Easier to Cut?

Improved Ductility

Annealing significantly enhances a material’s ductility. This property allows metals to bend without breaking. When a metal is annealed, it becomes more pliable. This increased flexibility means that cutting tools can manipulate the material with ease. For instance, when you cut an annealed piece, it deforms rather than cracking. This is crucial in applications where precision is vital. The ability to shape and form metals without fear of fractures improves the overall cutting process. Think of it as trying to cut a soft piece of clay versus a hard, brittle one. The softer material yields, making the task much easier.

To ensure your projects are executed with precision, consider using a Digital Caliper for Precision Measurements. This tool will help you achieve accurate cuts and measurements, ensuring your metalworking projects turn out just as you envision.

Reduced Hardness

Lowering a material’s hardness is another key benefit of annealing. Hardness can hinder the cutting process. When metals are too hard, they wear down cutting tools faster. This leads to more frequent tool replacements and increased costs. Annealed materials, being softer, reduce the strain on cutting tools. This results in longer tool life and less downtime for maintenance. Additionally, the smooth cutting action helps achieve finer finishes on the products. Imagine trying to slice through a rock versus a ripe tomato; the difference is striking. A soft annealed piece allows for smoother cuts and better results.

For those who are serious about their metalworking, investing in a good Welding Helmet with Auto-Darkening Filter is a must. It protects your eyes from harmful rays while allowing you to see your work clearly.

Uniform Grain Structure

A uniform grain structure plays a vital role in enhancing machinability. During annealing, the internal grain structure of a metal becomes more consistent. This uniformity allows for predictable cutting behavior. When a material has evenly distributed grains, it cuts more efficiently. This minimizes the chances of chipping or tearing during the cutting process. Think of it like slicing through a well-made loaf of bread; each slice is clean and even. In contrast, cutting through an uneven loaf can lead to jagged edges. A uniform grain structure ensures that the cutting process is smooth, facilitating better outcomes in manufacturing.

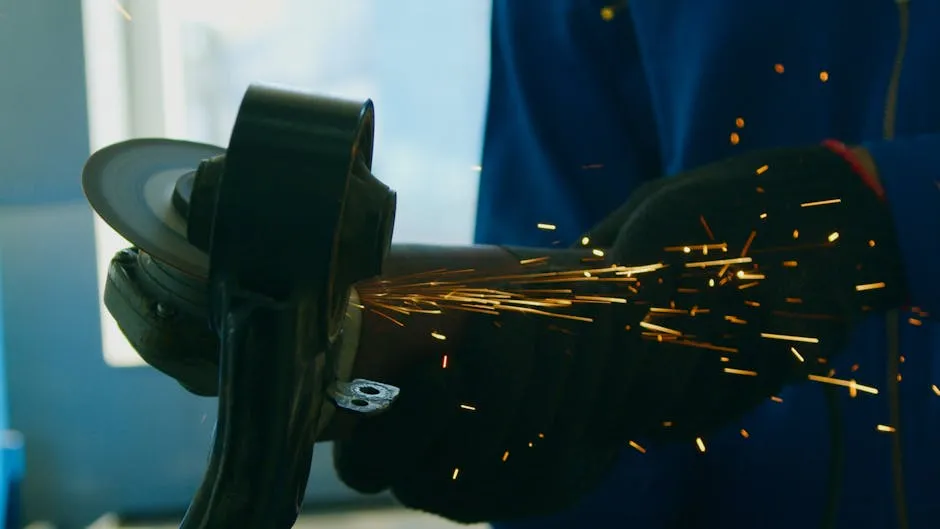

To shape your materials effectively, consider investing in a Cordless Angle Grinder for Metal Cutting. This versatile tool makes cutting and shaping metals a breeze, allowing you to achieve the desired finish with minimal effort.

Practical Applications of Annealed Materials

Manufacturing and Metalworking

Annealed materials play a vital role in manufacturing and metalworking industries. Companies that produce metal parts frequently rely on annealed metals for their excellent machinability. For example, in the production of automotive components, manufacturers use annealed steel to ensure that parts can be easily shaped and cut. This process minimizes tool wear and enhances production efficiency. Industries like construction, electronics, and appliances also benefit from annealed materials. In these fields, the ability to work with softer metals leads to improved fabrication methods and higher-quality finishes.

For those interested in expanding their knowledge, The Art of Metalworking: Techniques and Projects is a fantastic resource that provides hands-on projects and techniques for aspiring metalworkers.

Tool and Die Making

In tool and die manufacturing, annealed materials are essential. Toolmakers often use annealed steel and aluminum to create molds and dies. The improved ductility allows for precise shaping and forming. For instance, when creating complex shapes, the softer material reduces the risk of cracking during the machining process. This flexibility is crucial in producing high-quality tools that can withstand repeated use. Additionally, annealed materials ensure longer tool life, as they are less likely to chip or break under pressure.

To enhance your tool collection, consider a Heavy-Duty Clamps for Metalworking. These clamps will hold your workpieces securely, allowing you to focus on achieving the perfect cut without any movement.

Automotive and Aerospace Industries

The automotive and aerospace sectors heavily utilize annealed materials in critical components. In automotive manufacturing, parts like gears, axles, and frames often undergo annealing to enhance their performance and durability. Annealed steel provides the necessary strength while maintaining machinability, which is vital for mass production. Similarly, in aerospace, components such as turbine blades and structural parts benefit from the properties of annealed alloys. These materials offer a perfect balance of strength and weight, crucial for aircraft performance. Overall, the use of annealed materials in these industries leads to safer, more reliable products.

To further your understanding of metalworking history and techniques, consider reading Steel: A Design, Cultural, and Industrial History. This book provides insights into the material that has shaped our world.

FAQs

What is the annealing process in metallurgy?

Annealing is a heat treatment technique used in metallurgy. It involves heating a metal above its recrystallization temperature, holding it there, and then cooling it slowly. This process relieves internal stresses, increases ductility, and reduces hardness.

Why does annealing improve machinability?

Annealing improves machinability by increasing a material’s ductility and lowering its hardness. This makes it easier for cutting tools to manipulate the material, leading to smoother cuts and less tool wear.

Can any metal be annealed?

Not all metals can be annealed, but many ferrous and non-ferrous metals can benefit from the process. Common materials include carbon steel, aluminum, and copper, which typically see improved characteristics post-annealing.

How does the annealing process affect the mechanical properties of metals?

Annealing changes several mechanical properties of metals. It increases ductility, allowing for easier shaping and forming. Simultaneously, it reduces hardness, which can enhance workability and decrease the risk of cracking.

What are the common methods of annealing?

Common methods of annealing include full annealing, process annealing, and stress relief annealing. Each method serves different purposes, such as improving ductility, restoring properties after cold working, or relieving internal stresses in welded components.

Please let us know what you think about our content by leaving a comment down below!

Thank you for reading till here 🙂

And while you’re at it, why not treat yourself to a Portable Bluetooth Speaker for Music on the Go? It makes for a perfect companion while you work on your next metal masterpiece!

All images from Pexels